The Most Influential People in the wood kayak plans Industry and Their Celebrity Dopplegangers

Make 16,000 Projects With Step By Action Plans

... even if you don't have a large workshop or costly tools!

Each of the 16,000 projects are detailed enough to leave nothing to guesswork yet easy enough for beginners.

It includes complete guidelines from start to finish, leaving absolutely no uncertainty.

Here's what I'm discussing:

1. Detailed Guidelines

You get in-depth projects with action by action, A to Z instructions that makes structure projects extremely quickly, very simple and extremely enjoyable

.

With the simple "hold-you-by-the hand" guidelines, you can finish woodworking tasks in the little portion of the time it currently takes you.

It's like having a MASTER woodworker, at hand, directing you through the whole job.

detailed woodworking strategies.

2. Cutting & Materials List.

You get exact cutting and products list for each job.

You will have the ability to purchase specific quantities which means you'll stop squandering your hard earned cash on wrong wood, incorrect products or the wrong quantity.

It conserves time and lower waste. It saves cash. You'll invest more time building, less time worrying.

woodworking cutting list products.

3. Comprehensive Schematics.

With sharp and colorful schematics consisted of in each plan, there's simply no uncertainty involved. The level of information makes the most tough project a walk in the park!

When guidelines are THIS clear, your job BUILDS ITSELF. All the pieces simply "Click" into location.

You'll finish jobs in a fraction of the time it normally takes you.

woodworking jobs.

4. Views From All Angles.

You get to see EXACTLY how whatever ought to look PRIOR TO you construct them.

Most plans do not include this and merely assume. You'll end up structure something that doesn't look like the drawing!

You get elaborate details of every angle, every corner, every joint. The plans will NEVER leave you guessing or scratching your head over any detail.

wood projects strategies.

5. Suitable For Beginners & Professionals.

We have actually got plans that cover all levels of ability and competence. You do NOT require to be a master woodworker or have costly equipment to use our plans.

Whether you're a total newbie, an amateur woodworker with hand tools or an experienced pro, you'll find thousands of tasks that will match your level.

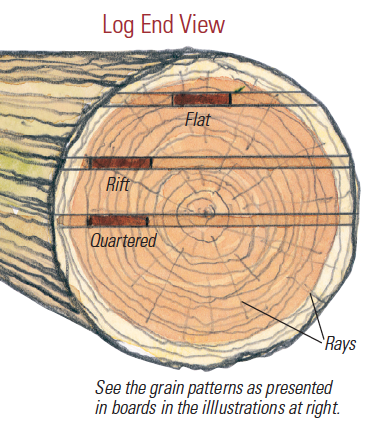

When seen from the end, a log's grain looks like a spider web (see the illustration at left). That grain as it presents in a board will inform you how it will react to cutting (see ideal illustrations). Those patterns (flat, rift and quartered) suggest where a board was harvested from a log. Riftsawn is the most challenging to predict which cutting direction will produce tearout.

Flatsawn Lumber.

Flatsawn lumber is the easiest grain to check out, and also can tear out excessively if you try to "run the piece against the grain" through a planer or jointer. The development rings in flatsawn stock are roughly parallel to the face, though they are curved. To joint or plane the faces, it's finest to check out the development ring lines on the edge closest to the center of the tree. Woodworkers say that you always desire to "cut uphill" on those lines. See the illustration at leading right to clearly understand what that indicates. All machines cut versus feed direction, suggesting that you must know the rotation of the cutterhead when using a jointer or planer. To mill the edges, read the instructions of the rays on the face. Read them near the center of the cathedral patterns and remember that you should never ever check out the cathedrals themselves.

Reading the rays on the face is simple on species like oak, sycamore and beech. It's more difficult to check out on types like maple and cherry, but still possible. On open-grained but scattered permeable species like mahogany and walnut, checked out the coarse cell structure on the face. And on softwoods like pine and spruce, you can read the resin canals, if the species has any. With practice, you can precisely read the grain a minimum of 95% of the time. Constantly test your choice by taking a very small cut, and if tearout takes place, turn the board the other instructions and try once again.

Quartersawn Lumber.

Drawing of quartersawn lumber from a planer.

Quartersawn stock is the opposite of flatsawn, in that the growth rings run perpen- dicular to the face. Again, believe of a spider web, where the concentric rings are like growth rings and the radial lines resemble the rays. So assess quartersawn stock in the opposite way to flatsawn stock. To cut the faces, look at the edges. The edge closest to the center will have tiny cathedral patterns (if appropriately quartersawn), however checked out the tiny rays going through them instead. To mill the edges, read the development ring lines on the faces. Want to the bottom illustrations to comprehend wood table plans the appropriate feed instructions and cutter rotation.

Riftsawn Lumber.

There is no precise way to check out riftsawn stock consistently because we do not see a correct cross-sectional view anywhere on the faces or edges. Nevertheless, if a board is riftsawn on one side however gets closer to flatsawn on the other side (nearer the center of the tree), that is a key. In other words, by checking out in the right places you can deal with the board as flatsawn if it is close to flatsawn in one area. If, on the other hand, the riftsawn board begins to become practically quartersawn on the other side (the outside of the tree), then seek to the growth rings on the face however actually near to the edge which would have been the outside of the tree. And treat it as quartersawn. This is harder, so you need to remain on your toes.